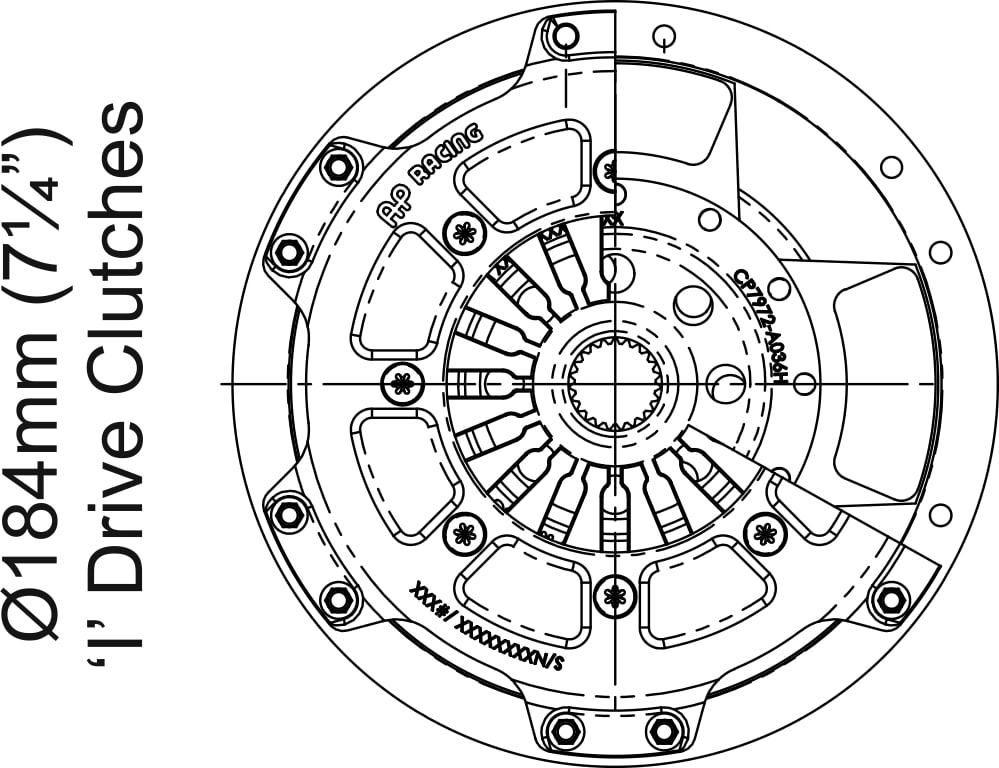

Ø184mm (7¼) 'I' Drive Clutch Types

‘I’ Drive was designed and developed to combat clutch drag to which sintered clutches are susceptible when operating under arduous service conditions. Conventional clutch designs typically feature external ‘jaws’ around the OD of the steel intermediate and main pressure plates, which can distort and to trap the legs of the aluminium cover, causing clutch drag.

‘I’ Drive features drive ‘tenons’ around the OD of the steel intermediate and main pressure plates which locate in internal jaws in the lightweight aluminium clutch cover, thereby eradicating the onset of clutch drag to which conventional drive arrangements are susceptible.

The ‘I’ Drive design has been proven via a program of dyno tests to compare durability at a challenging duty cycle, along side vehicle testing. The new is design currently being competed with in WRC and tested in Nascar with positive feedback the ‘I’ Drive clutch is maintaining performance under arduous operating conditions for significantly longer than the conventional clutch design.

In addition, ‘I’ Drive system benefits from an assymmetric design concept offering a radical look and improved stiiffnes,

reduced weight and also features an innovative new ‘wear plate’ design, to combat wear on the drive legs of the lightweight aluminium clutch cover where they are contacted by the steel plates (a problem common to all sintered clutches with aluminium covers). This comprises relatively thick wear ‘pads’ which are captivated into both drive faces of each of the aluminium cover drive-legs, providing a robust wear surface.